SERVICES

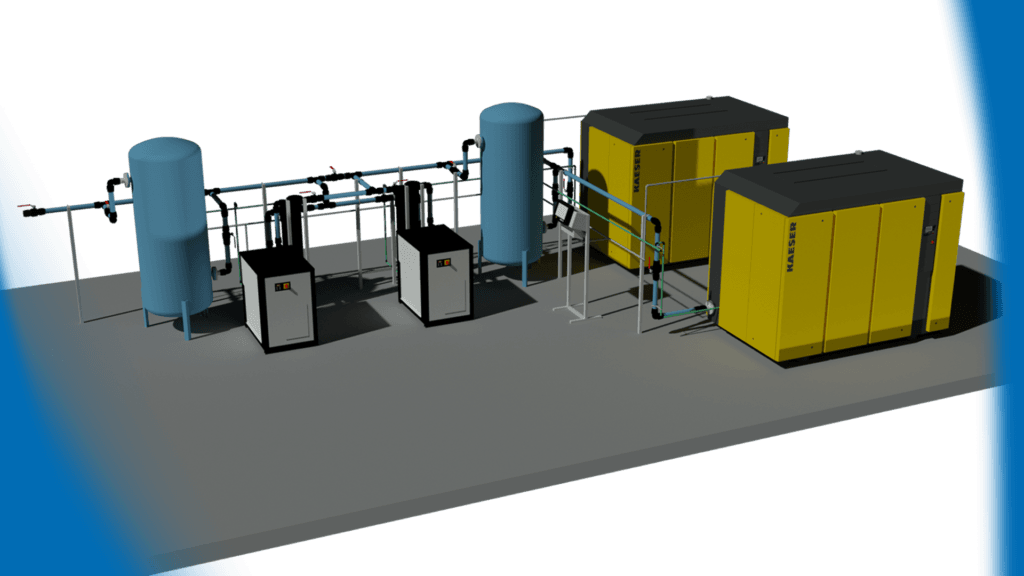

TURNKEY COMPRESSED AIR DESIGNING & ALUMINUM PIPELINE SOLUTIONS

Each compressed air system project is unique, as the need for compressed air varies with the application and there are many configuration options. Optimal design at the outset of the project will ensure:

- Safety of the people who will be using the compressed air

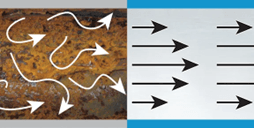

- Lower operating costs due to system efficiency

- Ideal performance of pneumatic equipment and tools

Worried about the below questions for your factory?

01.

How is the plant layout configured?

02.

What are the workstation locations and layouts (tools and equipment)?

03.

How far does the air system need to go (total distance/size of the factory)?

04.

How many drops will there be?

We are here to help you out. Reach out to us now and get your factory designed and equipped with the most efficient and sustainable compressed air network.

We will help you calculate the total airflow required for all your equipment. The diameter of the air system should be large enough to deliver the required amount of air at the required pressure to all the sampling points.

WHAT IS THE BEST AND IDEAL SOLUTION FOR INSTALLATION?

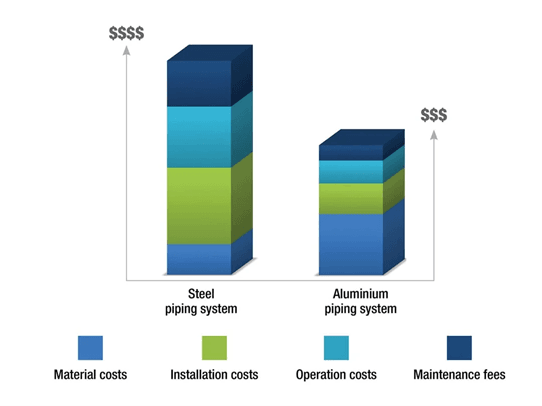

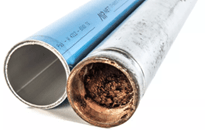

Depending on the type of material, it will have a different impact on efficiency, leak tightness, durability, adaptability, maintenance, installation, and overall cost over the long term.

Here, we provide AIRNET aluminum piping solutions. Aluminum has now become the industry standard for compressed air piping systems because it is both anti-corrosive, lighter and easy to handle.

AIRNET aluminum piping is very easy to install and saves time and labour costs when compared to traditional threaded or welded pipes.

GOAL

Quality Comes First

Complete Solution Providers For All Your Engineering Needs…

Build Quality

Technology

Sustainability

We are here to help you.

We’d love to hear from you! Whether you have a question, feedback, or need support, our team is here to assist you.